1390 Umshini wokusika wokunemba okuphezulu

Isibonisi somkhiqizo

Ipharamitha yobuchwepheshe

| Indawo yokusebenza | 1300*900mm | I-Laser Head Brand | Ama-Raytools |

| Amandla we-fiber laser | Ongakukhetha: 1000W/1500w/2000w/3000W njll. | Izingxenye Eziyinhloko | Imoto |

| Isivinini esikhulu sokusika | 0-40m/min | Isici:

| Kufakwe ngokugcwele |

| Phinda ukunemba kokuma | 0.02mm | Imodi yokusebenza | igagasi eliqhubekayo |

| ukunikezwa kwamandla kagesi | 220v/50Hz/60Hz | imoto nomshayeli | I-Japan YASKAWA servo motor & driver/French reducer |

| Izinga lokushisa kwemvelo | 0-35°C | Ifomethi Yomfanekiso Isekelwe | I-AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

| Isikhathi sokusebenza esiqhubekayo | Amahora angu-24 | Indawo Yokusika | 1300*900mm,1300*1300mm |

| Isisindo somshini | 1500kg | Amaphuzu Okuthengisa Abalulekile | Ukunemba okuphezulu |

| Impilo yemvelo ye-laser | Amahora angu-100000 | Isistimu yokudlulisela | Ukudluliswa kwesikulufu sebhola |

| Control Software | I-Cypcut | MAX ukusheshisa | 0.5G |

| Uhlelo Lokupholisa | Ukupholisa amanzi | Phinda ukunemba kwendawo:

| ±0.006mm |

Ukusika ukujiya

| Ipharamitha yokusika i-Laser | ||||||||

|

| 500W | 1000W | 2000W | 3000W | 4000W | 6000W | 8000W | |

| Okubalulekile | Ubukhulu | isivinini m/min | isivinini m/min | isivinini m/min | isivinini m/min | isivinini m/min | isivinini m/min | isivinini m/min |

| Insimbi ye-carbon | 1 | 8--13 | 15--24 | 24--30 | 30--42 | 40--55 | 60--80 | 70--90 |

| 2 | 3.0--4.5 | 5--7.5 | 5.5--8 | 7--9 | 8--10 | 9--12 | 10--13 | |

| 3 | 1.8--3.0 | 2.4--4 | 3.5-4.8 | 4--6.5 | 4.5--6.5 | 4--7 | 4--7 | |

| 4 | 1.3-1.5 | 2--2.4 | 2.8-3.5 | 3.5--4.5 | 4.0--5.0 | 4.2--5.5 | 4.7--5.5 | |

| 5 | 0.9--1.1 | 1.8--2 | 2.5--3 | 3--3.5 | 3.0--4.2 | 3.5--4.2 | 3.8--4.5 | |

| 6 | 0.6--0.9 | 1.4--1.6 | 1.8--2.6 | 2.5--3.2 | 3.0--3.5 | 3.0--4 | 3.3--4.2 | |

| 8 |

| 0.8--1.2 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | 2.2--3.2 | 2.5--3.5 | |

| 10 |

| 0.6--1.0 | 1.1-1.3 | 1.4--2.0 | 1.5--2.5 | 1.8--2.5 | 2.2--2.7 | |

| 12 |

| 0.5--0.8 | 0.9--1.2 | 1.2--1.6 | 1.4--2 | 1.6--2 | 1.8--2.1 | |

| 14 |

|

| 0.7-0.8 | 0.9--1.4 | 1.0--1.6 | 1.5--1.8 | 1.7--1.9 | |

| 16 |

|

| 0.6-0.7 | 0.8--1.2 | 0.8--1.2 | 0.8--1.5 | 0.9--1.7 | |

| 18 |

|

| 0.4--0.6 | 0.7--1 | 0.8--1.1 | 0.9--1.2 | 0.9--1.2 | |

| 20 |

|

|

| 0.6--0.8 | 0.7--1 | 0.8--1.1 | 1.0--1.5 | |

| 22 |

|

|

| 0.4--0.6 | 0.6--0.8 | 0.7--0.9 | 0.8--1.0 | |

| 25 |

|

|

|

| 0.3--0.5 | 0.4--0.6 | 0.5--0.7 | |

| Insimbi engagqwali | 1 | 8--13 | 18--25 | 24--30 | 30--42 | 40--55 | 60--80 | 70--90 |

| 2 | 2.4--5.0 | 7--12 | 10--17 | 18--21 | 20--30 | 30--42 | 40--55 | |

| 3 | 0.6--0.8 | 1.8--2.5 | 4--6.5 | 8--12 | 12--18 | 18--24 | 30--38 | |

| 4 |

| 1.2--1.3 | 3--4.5 | 6--9 | 8--12 | 10--18 | 18--24 | |

| 5 |

| 0.6--0.7 | 1.8-2.5 | 3.0--5.0 | 4--6.5 | 8--12 | 12--17 | |

| 6 |

|

| 1.2-2.0 | 3.0--4.3 | 4.0--6.5 | 6--9 | 8--14 | |

| 8 |

|

| 0.7-1 | 1.5--2.0 | 1.8--3.0 | 4--5 | 6--8 | |

| 10 |

|

|

| 0.8--1 | 0.8--1.5 | 1.8--2.5 | 3--5 | |

| 12 |

|

|

| 0.5--0.8 | 0.6--1.0 | 1.2--1.8 | 1.8--3 | |

| 15 |

|

|

|

| 0.5--0.8 | 0.6--0.8 | 1.2--1.8 | |

| 20 |

|

|

|

| 0.4--0.5 | 0.5--0.8 | 0.6--0.7 | |

| 25 |

|

|

|

|

| 0.4--0.5 | 0.5--0.6 | |

| 30 |

|

|

|

|

|

| 0.4--0.5 | |

| I-Aluminium | 1 | 4--5.5 | 6--10 | 20--25 | 25--40 | 40--55 | 55--65 | 80--90 |

| 2 | 0.7--1.5 | 2.8--3.6 | 7--10 | 10--18 | 15--25 | 25--35 | 35--50 | |

| 3 |

| 0.7--1.5 | 4--6 | 7--10 | 10--15 | 13--18 | 21--30 | |

| 4 |

|

| 2--3 | 4--5.5 | 8--10 | 10--12 | 13--18 | |

| 5 |

|

| 1.2-1.8 | 3--4 | 5--7 | 6--10 | 9--12 | |

| 6 |

|

| 0.7--1 | 1.5--2.5 | 3.5--4 | 4--6 | 4.5--8 | |

| 8 |

|

|

| 0.7--1 | 1.5--2 | 2--3 | 4--6 | |

| 10 |

|

|

| 0.5--0.7 | 1--1.5 | 1.5--2.1 | 2.2--3 | |

| 12 |

|

|

|

| 0.7--0.9 | 0.8--1.4 | 1.5--2 | |

| 15 |

|

|

|

| 0.5--0.7 | 0.7--1 | 1--1.6 | |

| 20 |

|

|

|

|

| 0.5--0.7 | 0.7--1 | |

| 25 |

|

|

|

|

|

| 0.5--0.7 | |

| Ithusi | 1 | 4--5.5 | 6--10 | 14--16 | 25--35 | 35--45 | 50--60 | 70--85 |

| 2 | 0.5--1.0 | 2.8--3.6 | 4.5--6.5 | 10--15 | 10--15 | 25--30 | 30--40 | |

| 3 |

| 0.5--1.0 | 2.5--3.5 | 5--8 | 7--10 | 12--18 | 15--24 | |

| 4 |

|

| 1.5--2 | 3.5-5.0 | 5--8 | 8--10 | 9--15 | |

| 5 |

|

| 1.4-1.6 | 2.5--3.2 | 3.5-5.0 | 6--7 | 7--9 | |

| 6 |

|

|

| 1.2--2.0 | 1.5--2.5 | 3.5--4.5 | 4.5--6.5 | |

| 8 |

|

|

| 0.7-0.9 | 0.8--1.5 | 1.6--2.2 | 2.4--4 | |

| 10 |

|

|

|

| 0.5--0.8 | 0.8--1.4 | 1.5--2.2 | |

| 12 |

|

|

|

|

| 0.6--0.8 | 0.8--1.5 | |

| 16 |

|

|

|

|

|

| 0.6--0.8 | |

Izingxenye Eziyinhloko

Isicelo

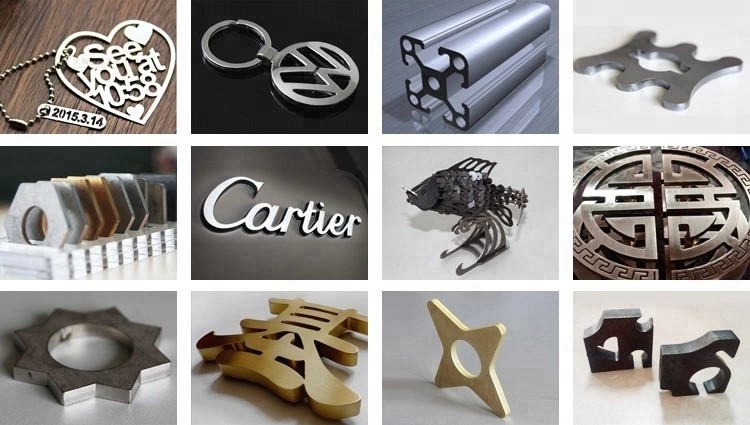

Imboni yohlelo lokusebenza:

I-1390 High Precision Laser Cutting Machine isetshenziswa kabanzi ekukhiqizeni i-Billboard, Ukukhangisa, Izimpawu, Izimpawu, Izinhlamvu Zensimbi, Izinhlamvu ze-LED, Impahla Yasekhishini, Izinhlamvu Zokukhangisa, I-Sheet Metal Processing, Izingxenye Zensimbi Nezingxenye, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Elevator Ware, Hardware Art Ware. Uhlaka, Izingxenye Ze-elekthronikhi, Ama-Nameplates, njll.ukuqinisekisa ukuthi ingasebenza ngangokunokwenzeka phakathi nenqubo yokusika i-laser.

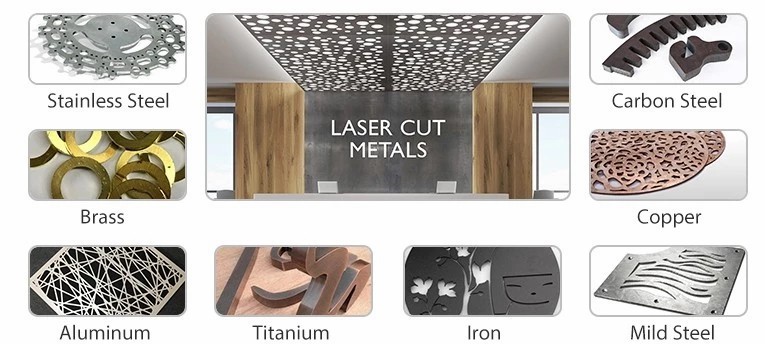

Izinto Zokusebenza:

Ishidi Lensimbi Engagqwali, I-Mild Steel Plate, I-Carbon Steel Sheet, I-alloy Steel Sheet, I-Spring Steel Sheet, Iron Plate, I-Iron Galvanized, Ishidi Eliqinile, I-Aluminium Plate, Ishidi Lethusi, Ishidi Lethusi, I-Bronze Plate, I-Gold Plate, I-Silver Plate, I-Titanium Plate, I-Metal Sheet, Insimbi, Insimbi njll.

Amasampula

Inzuzo

1.Ukusika kahle, kufika ku-0.05-0.1mm. Sebenzisa igesi elisizayo elifanelekile, wenze izimbotshana zibe bushelelezi futhi zibushelelezi, azidingi ukupholisha okwesibili.

2.Ukugxilisa ikhanda lokusika ngokuzenzakalelayo.ukusetshenziswa kwenzwa ye-capacitive ephezulu evela kwamanye amazwe, ukuphakama kwepuleti lokulandela eliguqukayo eligcwele.Ukulungisa ukuphakama kokusika ngokuzenzakalelayo okuvimbela ukungqubuzana, ungasika ipuleti elingalingani.

3. Umshini wokusika wamukela idrayivu ye-servo motor engenisiwe, ukungenisa imodyuli yomugqa enembayo ephezulu, esheshayo, ukunemba okuphezulu kuze kufike ku-0.01mm. Impilo ende yesevisi.

4.Ukusetshenziswa kwe-fiber lasers ethuthukisiwe, amadivaysi ayisisekelo athunyelwa kwamanye amazwe. Ukuzinza okuphezulu, impilo ende, azikho izinsiza, azinasondlo.

5.Idizayini yobungcweti yedivayisi yokutakula impushana yegolide, uthuli nothuli kuqoqe yonke into yokutakula. Ukuze ukulahlekelwa kube okungenani.

6.Embonini yobucwebe begolide nesiliva isistimu yokusika i-laser yangokwezifiso, enendlela yokwenza kahle, ukusika indawo yokuqala, izendlalelo eziningi, umsebenzi wesakhiwo, yonga isikhathi nezinto ezibonakalayo.

7.Usayizi omncane, ukusetshenziswa kwamandla okuphansi, ukunikezwa okuncane, ukugcinwa okulula. Ngomoya ocindezelweyo kungabuye kunqunywe, izindleko eziphansi.