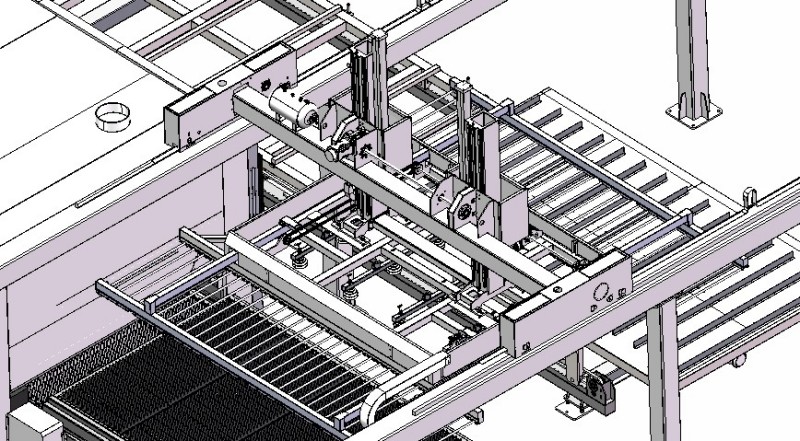

I-4020 i-gantry ye-Bilateral ilayisha futhi yehlisa ingalo yerobhothi

Isibonisi somkhiqizo

Izisetshenziswa nemingcele yobuchwepheshe

| Ubukhulu bosayizi wepuleti lokulayisha nokulayisha | 4000*2000 | mm |

| Ubuncane bosayizi wepuleti lokulayisha nokulayisha | 1500*1000 | mm |

| Ubukhulu obukhulu bokulayisha nokulayisha amapuleti | 50 | mm |

| Ubuncane bokulayisha kanye nobukhulu bepuleti lokulayisha | 0.8 | mm |

| Isisindo sepuleti elikhulu lokulayisha nokulayisha | 3000 | kg |

| Isisindo sokulayisha isendlalelo esisodwa semoto yezinto ezibonakalayo | 6 | T |

| Ukuphakama kokulayisha kwesendlalelo esisodwa semoto yezinto ezibonakalayo | 200 | mm |

| Isivinini sokuhumusha ingalo yemishini | 10-30 | m/min |

| Isivinini somshini wokuphakamisa izingalo | 5-10 | m/min |

| Isivinini sokushintshisana kwemoto kagesi | 10 | m/min |

| Amandla wezisetshenziswa | 10 | Kw |

| Ipayipi lokungenisa umoya wemishini | 12 | mm |

| Umthombo womoya wezisetshenziswa | 0.6-0.7 | Mpa |

| Izidingo zamandla | 3-isigaba 5-intambo 380V |

|

Ividiyo Yomshini

Uhlu lokucushwa kwezingxenye eziyinhloko zemishini

| Inombolo yomkhiqizo | Igama | Ibhrendi | Phawula |

| 1 | Ukuphakamisa umhlahlandlela womugqa | I-Taiwan HIWIN noma i-Japan SMG |

|

| 2 | Ukuphakamisa isilayidi esiwumugqa | I-Taiwan HIWIN noma i-Japan SMG |

|

| 3 | Isikrini sokuthinta esibonakalayo somshini womuntu | I-Shanghai Flexem |

|

| 4 | Isilawuli seVacuum | I-Taiwan KITA noma i-SNS |

|

| 5 | Umhlahlandlela womugqa wokuhumusha | I-Taiwan HIWIN noma i-Japan SMG |

|

| 6 | Humusha isilayidi esiwumugqa | I-Taiwan HIWIN noma i-Japan SMG |

|

| 7 | Isilawuli se-CNC | Japan OMRON |

|

| 8 | I-DC Power Supply | Japan OMRON |

|

| 9 | I-Relay | Japan OMRON |

|

| 10 | Inkomishi yokumunca | REZES |

|

| 11 | Izingxenye zomoya | I-Taiwan AIRTAC noma i-SNS |

|

| 12 | I-Servo Motor | Raynen | Uhlobo lwe-inertia enkulu |

| 13 | Isinciphisi esinembayo | I-Shanghai YINTONG noma i-Hangzhou KAXIELI | 8 arc imizuzu |

| 14 | Ama-rolling bearings | I-C&U Bearings | Isondlo-mahhala |

| 15 | Izinzwa ze-Photoelectric | I-CHIIB | Uchungechunge lwe-CHIIB |

| 16 | Umaphuli | Schneider | I-Delixi |

I-4020 i-gantry ye-Bilateral ilayisha futhi ikhipha ingalo yerobhothi Isixazululo Sobuchwepheshe

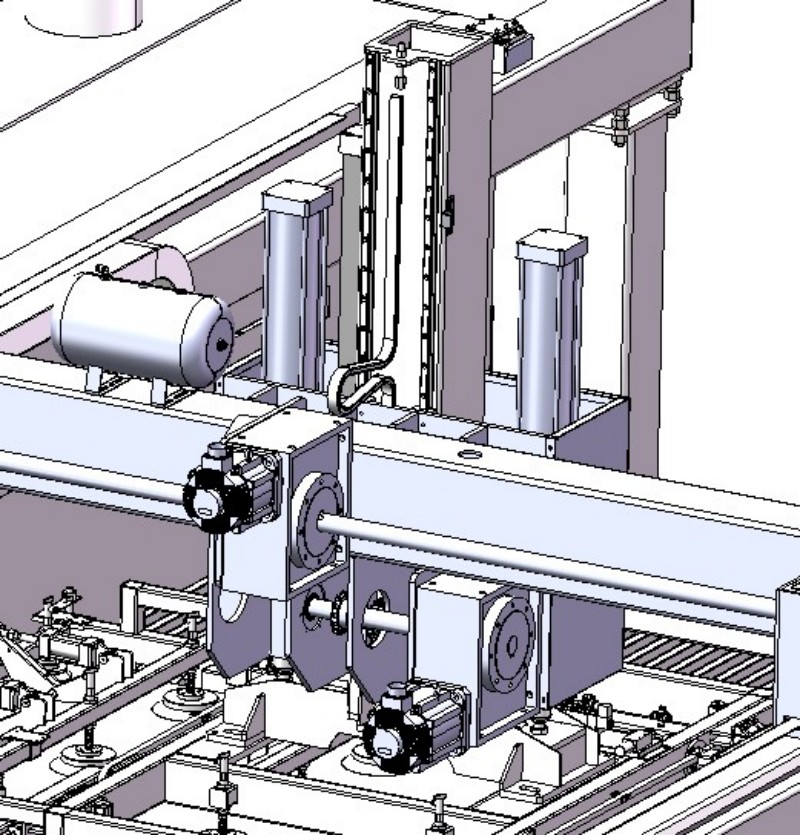

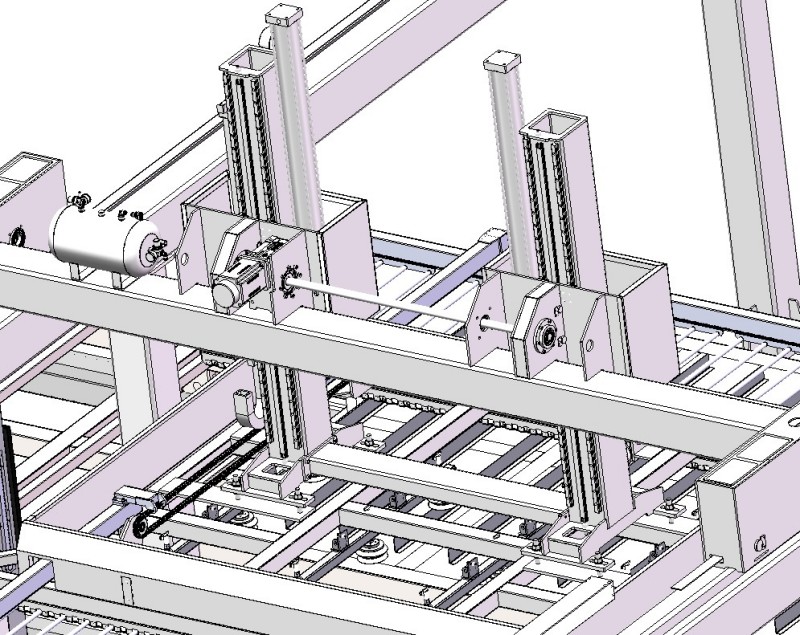

1.I-Manipulator ishayelwa i-servo motor ngokusebenzisa isinciphisi esinembayo, esinesamba sokuphakamisa i-stroke esingu-700mm kanye nokuhamba kwe-lateral okungu-4500mm (kushintshwa ngokuvumelana nezimo zangempela)

2.Amasethi amaningi ezinkomishi zokumunca ukumelana nowoyela afakiwe, isethi ngayinye yezinkomishi zokumunca ifakwe ivalvu eyenziwa ngesandla, engavalwa mathupha futhi ilungiswe ngokuya ngosayizi wepuleti. Ukunemba okuphindaphindiwe kokuma kwerobhothi eliphakelayo ngu-±2mm.

3.Isiphetho sifakwe idivayisi yokuhlukanisa amapuleti womoya ukuze kube lula ukuhlukaniswa kwamapuleti ngesikhathi sokuphakelwa okuzenzakalelayo. Qaphela: Ngenxa yamandla e-adsorption ahlukene kanye nokuqukethwe kwamafutha phakathi kwamapuleti, akuqinisekisiwe ukuthi amapuleti angahlukaniswa ngokuphelele ngempumelelo.Ukuhlukaniswa okusizwa mathupha kungenziwa ngokuvumelana nezimo zangempela.

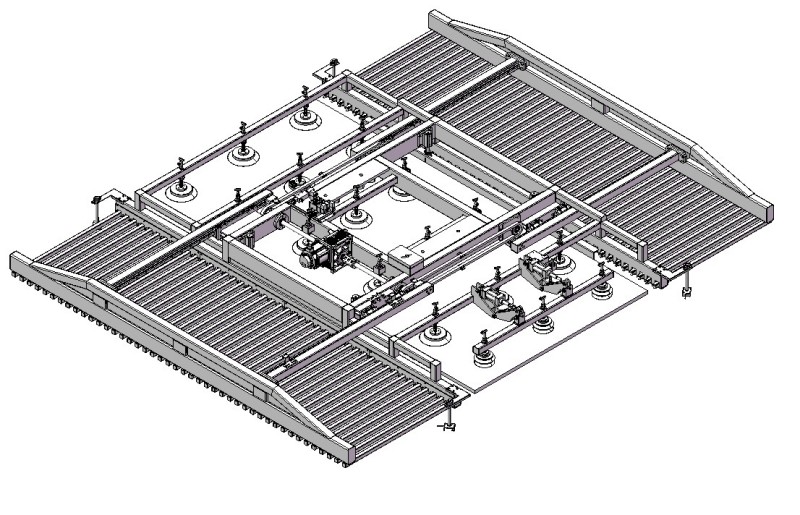

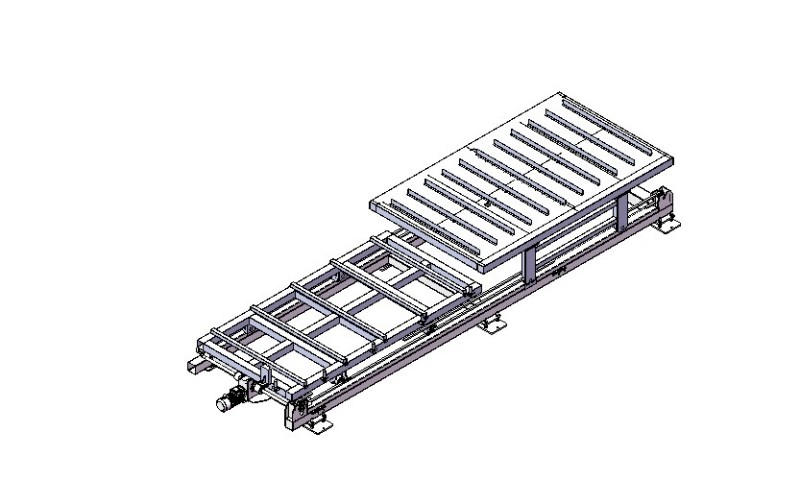

4.4. Ukulayisha nokulayishwa okuzenzakalelayo kufakwe inqola engu-1 enezingqimba ezimbili zikagesi (ungqimba olungaphezulu) ukuze umshini we-laser ugcine uhlaka lwemfucuza yomshini oqediwe ngemva kokusikwa, kanye nenqola yempahla kagesi engu-1 (ungqimba olungezansi) ukuze umshini we-laser unikeze izinto ezingavuthiwe.

5.Iloli lempahla lishayelwa injini enciphisa amandla futhi ifakwe idivayisi yokubhuleka kagesi. Ifakwe isihlukanisi kazibuthe esigudlukayo, kulula ukukhangisa ibhodi ukuze lihlukaniseke futhi kuthuthukiswe izinga lempumelelo lokuhlukanisa.

6.Ukwethula kusebenzisa i-manipulator enefoloko ekabili kanye nenkomishi yokudonsa elayishwayo exhunywe kusakhiwo sekholomu yokuphakamisa efanayo. Indlela yokukhipha iwuhlaka lwemfoloko yesokunxele nesokudla, imfoloko yokuthulula inebanga elifushane lokugijima kanye nezinga lokwehluleka eliphansi.

7.Izisetshenziswa ziqhutshwa i-servo ngokugcwele. Ukuphakamisa nokunyakaza kwe-lateral kwe-manipulator konke kuqhutshwa ama-servo motors anamandla aphezulu. Isistimu yokuphakamisa imishini ifakwe ama-lail guide rails, anesivinini sokugijima esisheshayo kanye nokunemba kokuma okuphezulu.

8.Isistimu yokulawula isebenzisa isikrini sokuthinta esingu-10-intshi esingenisiwe esinesistimu ye-CNC ehlakaniphile yesilawuli sohlelo lwe-Omron. Inezindlela zokusebenza ezizenzakalelayo nezandla. Zonke izilungiselelo, ukuqapha, nokulungisa iphutha kungasebenza ngesandla esikrinini, esisheshayo futhi esilula.

9.Indawo yokusebenza yalo mshini kufanele ihlangabezane nezidingo zezinga lokushisa elingu-10-45℃, umswakama ohlobene ngaphansi kuka-80%, kungabikho izinto ezivuthayo neziqhumayo, ukuphazamiseka okunamandla kazibuthe kagesi, akukho gesi egqwalayo, akukho ukuchaphazwa koketshezi, kanye nemvelo yokukhanya okuhle yasendlini.

Ukusetshenziswa Isingeniso

1.Umsebenzisi angashintsha phakathi kwemodi yokulayisha ngokuzenzakalelayo nemodi yokulayisha mathupha ngokusebenzisa isikrini esithintwayo ukuze sivumelane nezimo zokusebenza ezihlukene.

2.Indlela yokulayisha:Sebenzisa imfoloko yezinto ezihlukanisayo ezansi ukuze uvule, futhi inkomishi yokumunca i-vacuum yangaphakathi imunca ipuleti. I-shaft yokuphakamisa iyaphakanyiswa futhi ihanjiswe ngokuvundlile emshinini we-laser ukuze kubekwe ipuleti endaweni yesikhulumi se-laser.

3.Indlela yokukhipha impahla isebenzisa ukwakheka kwemfoloko kagesi kwesokunxele nakwesokudla. Imfoloko yokulayisha inebanga elifushane lokugijima kanye nezinga lokwehluleka eliphansi. Imfoloko yokuvula neyokuvala isebenzisa amazinyo emfoloko ensimbi yesikwele se-square, enomthamo omkhulu wokuthwala umthwalo kanye nekhono eliqinile lokulwa nokuguqulwa. Indawo yokuxhumana phakathi kwemfoloko yezinto ezibonakalayo nepuleti incane futhi ayiklwebheli ipuleti. Imfologo ephindwe kabili ivula iphinde ivale ngokuhambisanayo kuzo zombili izinkomba eduze kwesitimela somugqa futhi ishayelwa yi-electromagnetic brake motor.

4. Umzimba we-manipulator yokulayisha nokulayisha wenziwe ngepayipi lensimbi ye-manganese kanye nepuleti lensimbi lekhwalithi ephezulu, elishiselwe lilonke bese liphathwa ngokukhululeka kwengcindezi yokudlidliza, futhi licutshungulwe umshini wokugaya omkhulu we-CNC gantry. Inokuqina okuhle nokunemba okuphezulu. I-gantry beam nemilenze ixhunywe ngokulungisa ama-bolts, okulungele ukulungisa ukuvundlile kwe-gantry beam. I-manipulator yokulayisha nokulayisha ishayelwa yi-servo motor ngokusebenzisa isinciphisi esinembayo futhi ifakwe ama-rails omugqa womugqa angenisiwe. Indlela yokuphakamisa ifakwe isilinda sokulinganisa esivumelanayo ukuze kuthuthukiswe ukuzinza kokuphakamisa isivinini futhi kugwenywe izinkinga zokudlidliza ngesikhathi sokunyakaza kwendlela yokuphakamisa.

Umdwebo womthelela kanye nomdwebo we-Dimensional Outline

Izinto zokulungiselela ukufakwa kwemishini

1.Lungisa ukunikezwa kwamandla okungu-380V60A kanye nekhebula lamandla elingu-5-core 10mm² ukuze uxhume kudivayisi.

2.Umthombo womoya ocindezelwe onokucindezela kokusebenza okungu-0.6MPa kanye nepayipi lomoya elixhunywe kumathuluzi.

3.Misa izimpawu eziyisixwayiso zokuphepha kanye nezinqubo zokusebenza endaweni yokusebenza yesisetshenziswa.

Izinyathelo zokuphepha

1.Abasebenzi banqatshelwe ukungena endaweni yokusebenza yemishini ephathwayo ngaphakathi kwebanga lokusebenza;

2.Abasebenzi abangena endaweni yokusebenza badingeka ukuthi baqeqeshelwe ukuphepha;

3.Ngaphambi kokusebenzisa irobhothi, udinga ukuqinisekisa ukuthi izimo zokusebenza ziyahlangatshezwa yini.

Isevisi

---Isevisi yangaphambi kokuthengisa:

Ukubonisana Kwangaphambi Kokuthengisa Kwamahhala/Ukufakwa Kwesampula Kwamahhala

I-REZES Laser inikeza impendulo esheshayo yamahora ayi-12 ngaphambi kokuthengisa kanye nokuxhumana kwamahhala, Noma yiluphi uhlobo lokusekelwa kwezobuchwepheshe

etholakalayo kubasebenzisi.

Ukwenza Isampula Kwamahhala kuyatholakala.

Ukuhlolwa Kwesampula Kwamahhala kuyatholakala.

Sinikeza umklamo wesixazululo oqhubekayo kubo bonke abasabalalisi nabasebenzisi.

---Amasevisi angemva kokuthengisa :

Isiqinisekiso seminyaka engu-1.3 somshini wokusika we-fiber laser

2.Usekelo olugcwele lobuchwepheshe\ nge-imeyili, ucingo nevidiyo

3.Ukunakekela impilo yonke kanye nezingxenye ezisele.

4. Idizayini yamahhala yezakhiwo njengoba amakhasimende edingeka.

5. Ukufakwa kokuqeqeshwa kwamahhala nokusebenza kwezinduku.

FAQ

1. Q:Kungani kufanele sikukhethe?

A: Uma usikhetha, uzothola ikhwalithi ephezulu, isevisi engcono kakhulu, intengo enengqondo kanye newaranti ethembekile.

2.Q:Angiwazi umshini, ungakhetha kanjani?

A: Vele usitshele izinto zokwakha, ukujiya kanye nosayizi wokusebenza, ngizoncoma umshini ofanele.

3. Ungawusebenzisa kanjani umshini?

A: Sizoletha incwadi yesiNgisi nevidiyo enomshini kuwe.lif usadinga usizo lwethu olwengeziwe, sicela usithinte.

4.Q:Ngingakwazi yini ukuthola isampula ukuhlola izinga lomshini?

IMP: Yebo.Sicela usinike uphawu lwakho noma idizayini, amasampula wamahhala anganikezwa wona.

5.Q: Ingabe umshini ungenziwa ngokwezifiso ngokuvumelana nezidingo zami?

IMP: Impela, sineqembu eliqinile lezobuchwepheshe futhi sinolwazi olucebile. Umgomo wethu uwukwenza waneliseke.

6.Q:Ungasihlelela ukuthunyelwa?

A: Yebo.Singakwazi ukuhlela ukuthunyelwa kwamakhasimende ethu ngokufanele ngolwandle nangomoya. Amagama okuhweba okuthi FOB, ClF, CFR ayatholakala.