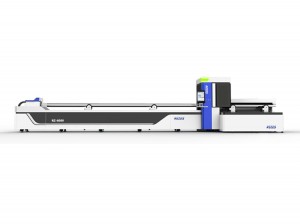

I-Double Platform Metal Sheet & Tube Fiber Laser Cutting Machine

Isibonisi somkhiqizo

Ipharamitha yobuchwepheshe

| Isicelo | I-Laser Cutting | Impahla Esebenzayo | Insimbi |

| Indawo Yokusika | 1500mm*3000mm | Uhlobo lweLaser | I-Fiber Laser |

| Control Software | I-Cypcut | I-Laser Head Brand | Ama-Raytools |

| I-Penumatic chuck | 20-350 mm | Ubude be-Chuck | 3m/6m |

| I-Servo Motor Brand | Yaskawa motor | Umbiko Wokuhlolwa Kwemishini | Kuhlinzekiwe |

| Ifomethi Yomfanekiso Isekelwe | I-AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC noma Cha | Yebo |

| Amaphuzu Okuthengisa Abalulekile | Ukunemba okuphezulu | Iwaranti yezingxenye eziyinhloko | Izinyanga ezingu-12 |

| Imodi yokusebenza | okuzenzakalelayo | Ukunemba Kokumisa | ±0.05mm |

| ukunemba kokubeka kabusha | ±0.03mm | Ukusheshisa Okuphakeme | 1.8G |

| Izimboni Ezisebenzayo | Amahhotela, Izitolo Zezinto Zokwakha, Imboni Yokukhiqiza | Izingxenye zomoya | I-SMC |

| Imodi yokusebenza | igagasi eliqhubekayo | Isici | Inkundla ekabili |

| Isivinini sokusika | kuye ngamandla nokuqina | Control Software | I-Tubepro |

| Ukusika Ukujiya | 0-50 mm | I-Guiderail Brand | HIWIN |

| Izingxenye zikagesi | schneider | Isikhathi sewaranti | 3 iminyaka |

Ukugcinwa komshini

1.Ukugcinwa kwesistimu yokupholisa

Amanzi angaphakathi kwe-cooler yamanzi adinga ukushintshwa njalo, futhi imvamisa yokushintshwa ngokuvamile iyinyanga eyodwa. Umshini wokupholisa amanzi unesibopho sokupholisa i-laser nezinye izingxenye zemishini njengamanzi ajikelezayo. Kulula ukwenza isikali lapho izinga lamanzi lisetshenziswa isikhathi eside, ngaleyo ndlela kuvinjwe indlela yamanzi futhi kubangele ukugeleza kwamanzi kwehle futhi kunciphise umphumela wokupholisa. Ngakho-ke, ukushintshwa kwamanzi okuvamile kuyinkinga eyinhloko. Amanzi kufanele ahlanjululwe ngangokunokwenzeka. Uma kungekho mbandela, amanzi ahlanjululwe angakhethwa. Umkhiqizi ngamunye unezidingo zekhwalithi yamanzi, futhi kubalulekile ukuhlangabezana nezidingo. Uma kungenjalo, ukusetshenziswa kwekhwalithi yamanzi engafaneleki isikhathi eside kuzodala ukungcola kwangaphakathi kwe-laser.

2.Ukugcinwa kwesistimu yokususa uthuli

Ukusetshenziswa isikhathi eside kwesiphephetha-moya kuzobangela uthuli oluqinile oluningi ngaphakathi kwesiphephetha-moya, okuzodala umsindo omkhulu futhi akusizi ukuqeda nokuqeda iphunga. Uma isiphephetha-moya singamunceli ngokwanele, ugesi uvalwa kuqala, ipayipi lokungenisa umoya kanye nepayipi lokukhipha umoya ku-fan kuyasuswa, kukhishwe uthuli olungaphakathi, bese isiphephetha-moya sigudluzwa, bese kudonswa ama-fan blade aze ahlanzeke. Bese ufaka ifeni.

3.Optical system ukugcinwa

I-laser ibonakala kusukela ku-lens futhi igxile ngaphandle kwekhanda le-laser. Ngemuva kokuthi okokusebenza kusebenze isikhathi esithile, ingaphezulu le-lens lizombozwa ngothuli oluthile, oluzothinta kakhulu ukubonakala kwelensi kanye nokudluliswa kwelensi, okuholela ekwehleni kwamandla e-laser. Uthuli. Nokho, qaphela lapho uhlanza. Ilensi iyinto entekenteke. Kufanele uyisebenzise nento elula noma into eqinile ukuze uthinte ilensi.

Izinyathelo zokuhlanza i-lens kanye nezinyathelo zokuphepha zimi kanje: Okokuqala, sebenzisa uboya bekotini kanye ne-ethanol ukuze usule ngokucophelela phakathi nendawo yelensi ukuya onqenqemeni. I-lens idinga ukusulwa kahle. Ukugqoka okuphezulu akufanele konakaliswe. Phakathi nenqubo yokusula, yiphathe ngobumnene ukuze ingawi. Uma ufaka isibuko esigxilisa ingqondo, qiniseka ukuthi ugcina uhlangothi lwe-concave lubheke phansi. Ngaphezu kwalokho, inani le-ultra-high-speed perforations ngokuvamile liyancipha ngangokunokwenzeka, futhi ukusetshenziswa kwe-perforations evamile kungandisa impilo yesibuko sokugxila.

4. Ukugcinwa kwesistimu yokudlulisa

Emshinini wokusika we-laser, uhlelo lokudlulisela lulingana nesithende nonyawo lomuntu. Uhlelo lokudlulisela luthinta ngqo ukusebenza okuvamile nempilo yesevisi yemishini. Umshini wokusika i-laser uzokhipha intuthu ngesikhathi sokusika isikhathi eside. Uthuli olucolekile luzongena emishinini ngesembozo sothuli bese lunamathisela endaweni yokubeka ujantshi. Ukuqoqwa kwesikhathi eside kuzokwandisa amazinyo esitimela somhlahlandlela. Ukuguga kwe-strip, inkomba ye-rack ekuqaleni iyisesekeli esiyinkimbinkimbi, futhi isikhathi eside sizodala umonakalo kusilayidi kanye negiya. Ngakho-ke, umzila wesitimela kufanele uhlanzwe njalo ngokususa uthuli. Ngemuva kokuhlanza uthuli olufakwe ku-rack rack, i-rack igcotshwa ngamafutha futhi isitimela sigcotshwa ngamafutha okugcoba.

Ividiyo Yomshini

Metal Sheet & Tube Fiber Laser Cutting Machine