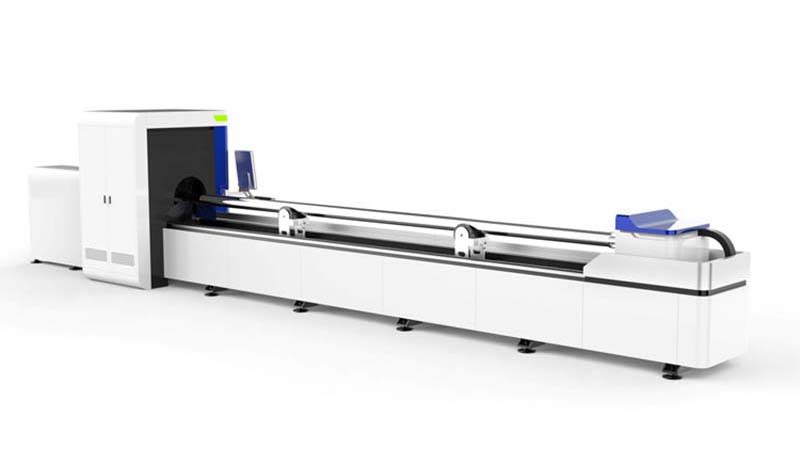

Ngokuthuthuka okusheshayo kobuchwepheshe be-laser,imishini yokusika ipayipi ye-laserziya ngokuya zisetshenziswa kabanzi ezimbonini eziningi. Ukuvela kwemishini yokusika ipayipi le-laser kulethe izinguquko ezihlasimulisayo enqubweni yokusika yemboni yamapayipi ensimbi evamile. Umshini wokusika amapayipi we-laser unezici zokuzenzakalela okuphezulu, ukusebenza kahle okuphezulu, nokukhishwa okuphezulu. Ngamapayipi ezinto ezihlukahlukene, asikho isidingo sokushintsha ama-saw blades ahambisanayo, futhi asikho isidingo sokumisa phakathi nendawo. Ifaneleka kakhulu ekukhiqizeni ngobuningi.

Ukuze kugcinwe ukusebenza okuphezulu komshini wokusika ipayipi le-laser, kuyadingeka ukugcina imishini njalo, ngakho-ke ungagcina kanjani umshini wokusika ipayipi? Ngaphezu kokunakekelwa kombhede wemishini, ukunakekelwa kwe-chuck nakho kubaluleke kakhulu. Okulandelayo amathiphu angu-4 okugcina i-chuck.

1. Ukuze kugcotshwe i-chuck, sebenzisa okokugcoba ku-chuck njalo ukuze uqinisekise ukuthi i-chuck isengaba nokunemba okuphezulu ngesikhathi sokunyakaza. Naka lapho ugcoba. Ukugcotshwa okungalungile kungase kubangele i-pneumatic chuck ukuthi yehluleke ukusebenza ngendlela evamile lapho umfutho womoya uphansi, amandla okubamba ayancipha, ukunemba kokubamba kuphansi, ukugqokwa akujwayelekile noma kubambekile, ngakho-ke naka ukusebenza okulungile kokugcobisa lapho ugcoba .

1. Ukuze kugcotshwe i-chuck, sebenzisa okokugcoba ku-chuck njalo ukuze uqinisekise ukuthi i-chuck isengaba nokunemba okuphezulu ngesikhathi sokunyakaza. Naka lapho ugcoba. Ukugcotshwa okungalungile kungase kubangele i-pneumatic chuck ukuthi yehluleke ukusebenza ngendlela evamile lapho umfutho womoya uphansi, amandla okubamba ayancipha, ukunemba kokubamba kuphansi, ukugqokwa akujwayelekile noma kubambekile, ngakho-ke naka ukusebenza okulungile kokugcobisa lapho ugcoba .

2. Sebenzisa amafutha e-molybdenum disulfide, ngokuvamile amafutha amnyama, bese ujova igrisi ku-chuck nozzle kuze kube yilapho igrisi lichichima indawo yomhlathi noma imbobo engaphakathi ye-chuck. Uma i-chuck isebenza ngesivinini esikhulu isikhathi eside noma isebenzisa ukucubungula okusizwa umoya-mpilo isikhathi eside, ukuthambisa okwengeziwe kuyadingeka, futhi imvamisa yokugcoba kufanele ilungiswe ngokuvumelana nezimo zangempela zokusebenza.

3. Ngemuva kokuthi ukucubungula sekuqediwe njalo ngesikhathi esithile, kuyadingeka ukusebenzisa isibhamu somoya esiphezulu ukuze ubhekane nezinsalela zothuli ku-chuck ngokwayo kanye ne-slideway. Kunconywa ukuhlanza imihlathi ye-chuck njalo ezinyangeni ezingu-3-6 ukuze kugcinwe indawo ehlanzekile futhi igcobe. Hlola ukuthi izingxenye ziphukile futhi zigugile, bese uzishintsha uma ukuguga kubucayi. Ngemuva kokuhlolwa, imihlathi kufanele igcotshwe kahle futhi ifakwe ngaphambi kokusetshenziswa.

4. Ama-workpiece akhethekile noma ama-workpiece angajwayelekile adinga ukuboshelwa futhi acutshungulwe ngama-chucks athile. I-chuck ejwayelekile yokusika ipayipi le-laser ifanele ukuma kweshubhu elilinganayo nelivaliwe. Uma uyisebenzisela ukuphoqa izinto zokusebenza ezingajwayelekile noma ezingajwayelekile, izodala ukungahambi kahle kwe-chuck; uma umfutho wokunikezwa komoya we-chuck uphezulu kakhulu, i-chuck izoba ngaphansi kwengcindezi ephezulu noma ngemuva kokuvala I-chuck iphinde ibambe ucezu lomsebenzi, okuzonciphisa impilo ye-chuck futhi kubangele izinkinga ezifana nokuchithwa kwe-chuck ngokweqile.

5. Vimbela insimbi eveziwe ye-chuck ukuthi ingagqwali. Ukuvimbela ukugqwala kungenye iphuzu elibalulekile. Ukugqwala kwe-chuck kuzonciphisa amandla okubamba futhi akukwazi ukubopha ucezu lokusebenza, okuthinta kakhulu ukunemba nokusebenza kahle komkhiqizo.

Indlela engenhla iyindlela eyinhloko yokugcina umshini wokusika ipayipi le-laser. Yiqiniso, ukusetshenziswa ngokucophelela komqhubi kanye nezinyathelo zokusebenza ezilinganiselwe zabasebenzi nazo ziyizici ezibalulekile zokugcina ukusebenza komshini wokusika ipayipi.

Isikhathi sokuthumela: Jan-19-2023