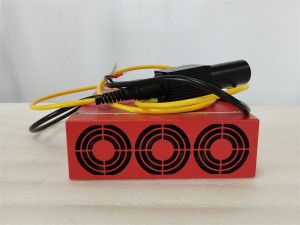

I-REZES EXHAUSE FAN 550W 750W IYADAYISWA

Isibonisi somkhiqizo

Ipharamitha eyinhloko

Ukucaciswa okwengeziwe

| Le yindawo ka Origin | Jinan, Shandong | Isimo | Okusha |

| Iwaranti | 3 iminyaka | Uhlobo Lwezingxenye Ezisele | I-Laser Exhaust Fan |

| Amaphuzu Okuthengisa Abalulekile | Impilo Emide Yenkonzo | Isisindo (KG) | 9.5 KG |

| Amandla | 550W/750W | I-Voltage yokufaka | 220V 50HZ |

| Ivolumu yomoya | 870/1200 m3/h | Ingcindezi | 2400 Pa |

| I-Inlet/Outlet ububanzi | 150mm | Ukuzungezisa | 2820r/min |

| Isevisi yangemuva kokuthengisa Inikeziwe | Izingxenye ezisele zamahhala, ukwesekwa kwezobuchwepheshe kwevidiyo | Uhlobo lwephakheji | iphakethe lebhokisi |

| Ngemva Kwesevisi Yewaranti | Usekelo lobuchwepheshe bevidiyo | Ukukhweza | Ukuma Kwamahhala |

| isikhathi sokuthumela | Phakathi kwezinsuku ezingu-3-5 | Isicelo | Co2 Laser Engraving Machines |

Isondlo

Ukugcinwa kwefeni yokukhipha umoya nezinye izingxenye zomshini wokusika we-laser we-Co2

1. Ukuhlanzwa kwefeni ye-exhaust:

Uma i-fan isetshenziswa isikhathi eside, uthuli oluqinile luzonqwabelana ku-fan, okuzokwenza ifeni ikhiphe umsindo omkhulu, futhi ayihambisani nokukhipha kanye nokuqeda iphunga. Uma amandla okudonsa efeni enganele futhi nentuthu ekhishwa yintuthu ibushelelezi, qala ngokuvala amandla, khipha i-air inlet nama-outlet ducts ku-fan, khipha uthuli ngaphakathi, bese uphendulela ifeni phezulu, bese udonsa ama-fan blades ngaphakathi kuze kube yilapho ehlanzekile. , bese ufaka ifeni.

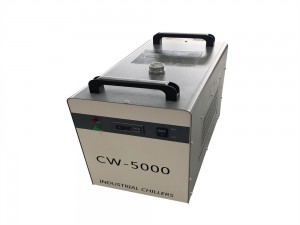

2.Ukushintshwa kwamanzi kanye nokuhlanza ithange lamanzi (kunconywa ukuhlanza ithange lamanzi bese ubuyisela amanzi ajikelezayo kanye ngesonto)

Qaphela: Qiniseka ukuthi ishubhu le-laser ligcwele amanzi ajikelezayo ngaphambi kokuba umshini usebenze.

Izinga nokushisa kwamanzi ajikelezayo kuthinta ngqo impilo yesevisi ye-laser tube. Kunconywa ukusebenzisa amanzi ahlanzekile futhi ulawule izinga lokushisa lamanzi elingaphansi kuka-35°C. Uma idlula i-35 ° C, amanzi ajikelezayo adinga ukushintshwa, noma ama-ice cubes engeziwe emanzini ukuze kuncishiswe izinga lokushisa kwamanzi (kunconywa ukuthi umsebenzisi akhethe into epholile, noma asebenzise amathangi amanzi amabili).

Ukuhlanza ithange lamanzi: qala ngokuvala amandla kagesi, khipha ipayipi elingenisa amanzi, vumela amanzi eshubhu le-laser azigelezele ethangini lamanzi, vula ithange lamanzi, ukhiphe iphampu yamanzi, futhi ukhiphe ukungcola empompini yamanzi. Hlanza ithange lamanzi, buyisela amanzi ajikelezayo, buyisela iphampu yamanzi ethangini lamanzi, faka ipayipi lamanzi elixhuma iphampu yamanzi endaweni yokungena amanzi, bese uhlela amalunga. Amandla empompini yamanzi yedwa futhi uyiqhube imizuzu engu-2-3 (ukugcwalisa ishubhu ye-laser ngamanzi ajikelezayo).

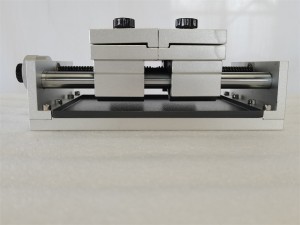

3. Ukuhlanzwa kwezinsimbi eziqondisayo (kunconywa ukuthi zihlanzwe njalo ngemva kwamasonto amabili, kuvalwe)

Njengenye yezingxenye eziyinhloko zemishini, isitimela somhlahlandlela kanye ne-linear shaft isetshenziselwa ukuqondisa nokusekela. Ukuze kuqinisekiswe ukunemba okuphezulu komshini womshini, ama-rails awo okuqondisa kanye nemigqa eqondile kuyadingeka ukuze kube nokunemba okuphezulu kokuqondisa nokuzinza okuhle kokunyakaza. Ngesikhathi sokusebenza kwemishini, kuzokwenziwa uthuli olukhulu nentuthu edlayo ngesikhathi kucutshungulwa ucezu lokusebenzela, futhi le ntuthu nothuli kuzofakwa phezu kukaloliwe oqondisayo kanye ne-axis yomugqa isikhathi eside, okunomthelela omkhulu ekucutshungulweni okunembayo kwemishini, futhi kuzokwakhiwa amabala okuCorrosion ebusweni bomugqa womugqa we-rail emfishane yokuphila kwensiza yensiza. Ukuze wenze umshini usebenze ngokujwayelekile nangokuzinza futhi uqinisekise ikhwalithi yokucubungula yomkhiqizo, kuyadingeka ukwenza umsebenzi omuhle ekunakekeleni kwansuku zonke kwesitimela somhlahlandlela kanye ne-axis yomugqa.

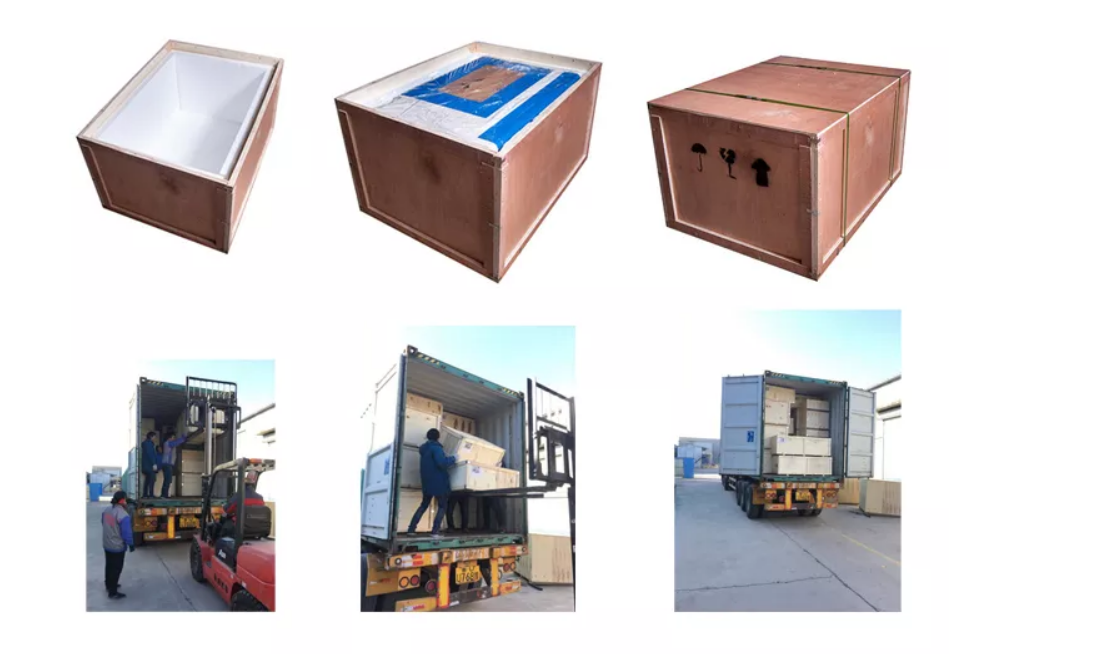

Iphakheji &Ukuthumela