Umshini Wokushisela Irobhothi Laser

Isibonisi somkhiqizo

Ipharamitha yobuchwepheshe

| Irobhothi le-Six-Axis | I-Tuling | Izingxenye Eziyinhloko | Umthombo we-Laser |

| Ukusetshenziswa | Weld Metal | Ubukhulu. Amandla Okukhiphayo | 2000W |

| Impahla Esebenzayo | Insimbi | Cnc Noma Cha | Yebo |

| Imodi Yokupholisa | Ukupholisa Amanzi | Amasistimu kagesi kanye ne-Pneumatic | Schneider |

| Ubude begagasi | 1090Nm | Laser Amandla | 1000w/1500w/2000w |

| Isisindo (Kg) | 600 Kg | Isitifiketi | Ce, Iso9001 |

| Izingxenye Eziyinhloko | I-Fiber Laser Source, i-Fiber, i-Handle Laser Welding Head | Amaphuzu Okuthengisa Abalulekile | Ukunemba okuphezulu |

| Umsebenzi | Metal Ingxenye Laser Welding | Ubude be-Fiber | ≥10m |

| Izimboni Ezisebenzayo | Amahhotela, Izitolo Zezingubo, Izitolo Zezinto Zokwakha | Izingxenye Eziyinhloko | Umthombo we-Laser |

| Imodi Yokusebenza | Ishayekile | Ngemva Kwesevisi Yewaranti | Ukusekela ku-inthanethi |

| I-Focal Spot Diameter | 50μm | Ukufakwa Okuphezulu | 1730 mm |

| Ukuhlolwa Okuphumayo kwevidiyo | Kuhlinzekiwe | Ifomethi Yomfanekiso Isekelwe | Ai, Plt, Dxf, Dwg, Dxp |

| Le yindawo ka Origin | I-Jinan, Isifunda saseShandong | Isikhathi sewaranti | 3 Iminyaka |

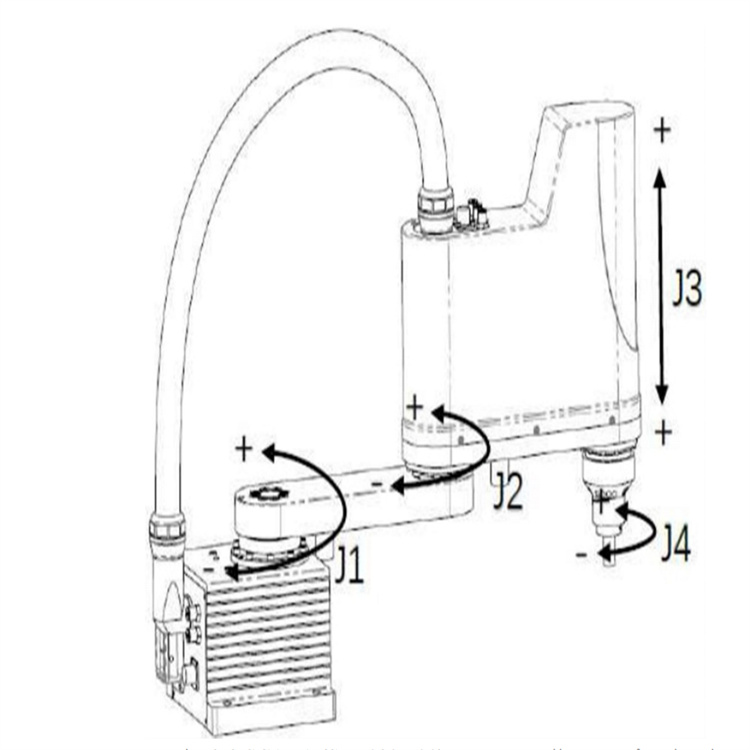

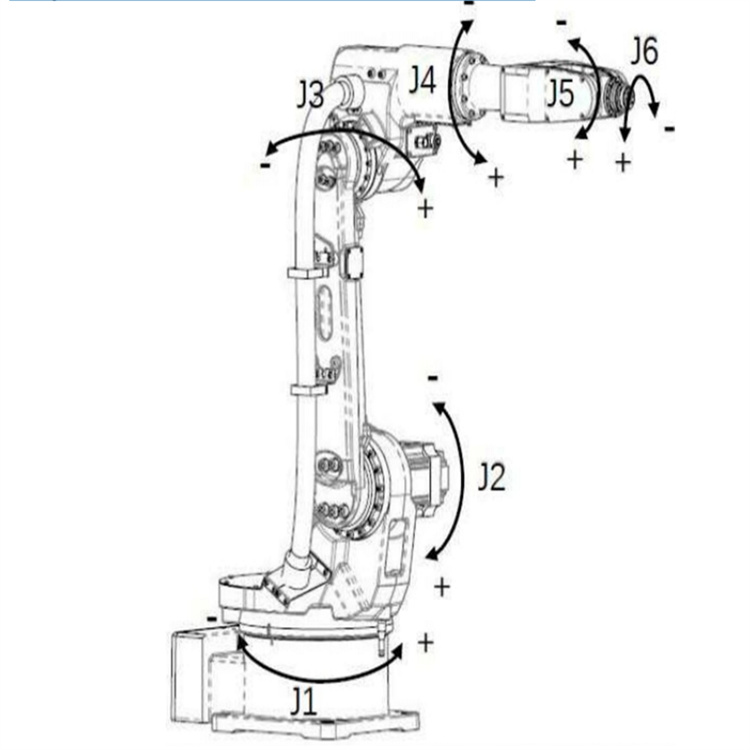

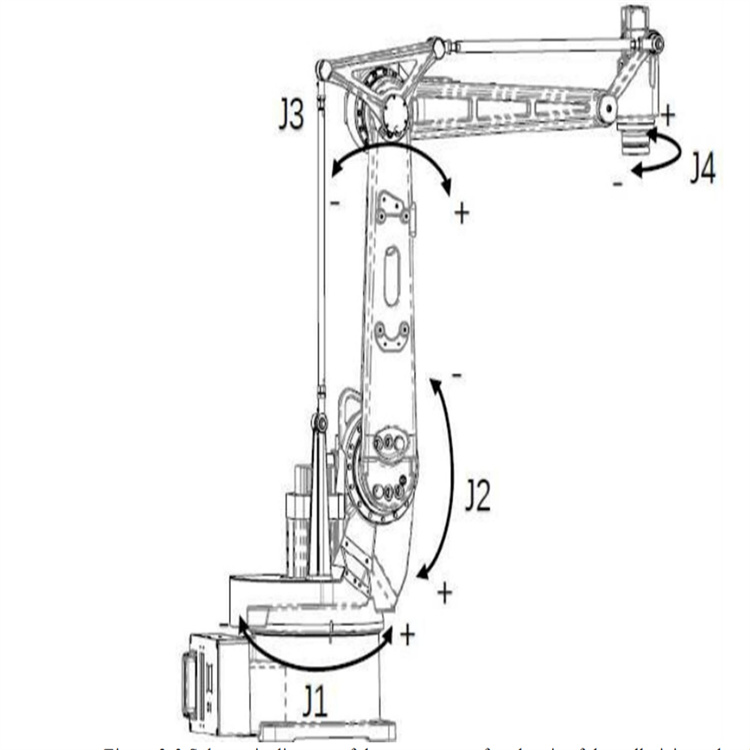

Ingalo yerobhothi

I-axis yerobhothi ingaba i-axis ejikelezayo noma i-axis yokuhumusha, futhi imodi yokusebenza ye-eksisi inqunywa isakhiwo somshini. I-axis yerobhothi ihlukaniswe yaba yi-axis enyakazayo yomzimba werobhothi kanye ne-eksisi yangaphandle. I-shaft yangaphandle ihlukaniswe ngetafula elislayidayo kanye ne-positioner. Ngaphandle uma kucaciswe ngenye indlela, i-axis yerobhothi isho i-eksisi enyakazayo yomzimba werobhothi.

Amarobhothi e-Turing ahlukaniswe abe izinhlobo ezintathu zamarobhothi ezimboni:

Irobhothi le-Industrial six-axis: kufaka phakathi ama-axes ayisithupha okuzungezisa

I-SCRA: iqukethe izimbazo ezintathu zokuzungezisa kanye ne-eksisi eyodwa yokuhumusha

I-Palletizing manipulator: kufaka phakathi ama-shaft amane ajikelezayo Ukunyakaza okuhlangene kwerobhothi kuboniswa emfanekisweni.

Ukusetshenziswa komshini wokushisela we-Robot

1.Inkundla Yokukhiqiza Imishini

Ngokuqiniswa kwemisebenzi yokushisela embonini yokukhiqiza imishini, ukusebenza kokushisela kunezimo zokusebenza ezingezinhle ngokwemvelo kanye nemisebe yokushisa emikhulu, okuwumsebenzi oyingozi kakhulu. Kukhona nemishini eminingi emikhulu ekukhiqizeni imishini, okwandisa nobunzima bokushisela. , Irobhothi elishiselayo liwumshini ozenzakalelayo owenza umsebenzi wokushisela, okhulula umfutho wabasebenzi futhi usize ukuthuthukisa izinga lokuzenzakalelayo emkhakheni wokukhiqiza imishini.

2.Izingxenye zezimoto nezimoto:

Eminyakeni yakamuva, ukuze kuhlangatshezwane nezidingo zomphakathi, imboni yezimoto ikhombise intuthuko ehlukahlukene. I-welding yendabuko ayikwazi ukuhlangabezana nezidingo zokushisela eziphezulu zokukhiqiza izingxenye zezimoto nezimoto. , I-welding seam yinhle futhi iqinile. Ezingqungqutheleni eziningi zesimanje zokukhiqiza izimoto, sekusungulwe imigqa yokuhlanganisa amarobhothi okushisela.

3.Izisetshenziswa zikagesi:

Inkambu yemishini kagesi inezidingo eziphakeme kakhulu zekhwalithi yokushisela. Ngokukhula kwesidingo semishini ye-elekthronikhi emphakathini, okokusebenza kwe-elekthronikhi nakho kubhekene nezinselelo ezinzima ngenkathi kuthuthuka ngokushesha. Amarobhothi okushisela angakwazi ukuzinzisa ikhwalithi yokushisela kuyilapho eqinisekisa ukusebenza kahle kokukhiqiza. I-welding enembile yemishini iphakeme ngokuphindwe kathathu kuya kane kunomsebenzi wezandla.

4. Umkhathi:

Esakhiweni sendiza, kunezingxenye zomzimba zokushisela ezicishe zibe yi-1,000, futhi zicishe zibe ngu-10,000 izingxenye ezihilelekile. Iningi lezingxenye ezibalulekile ezithwala umthwalo zendiza zisebenzisa izinto ezishiselwe. Umzimba wendiza ungaphansi kwengcindezi enkulu ngesikhathi sokundiza, ngakho ukushisela Izimfuneko ziqinile uma kuqhathaniswa, futhi irobhothi elishiselayo lingakwazi ukusetha ngokuguquguqukayo imingcele yokushisela ngobuchwepheshe bokulandelela umphetho we-welding othomathikhi ukushisela isakhiwo sendiza ngokunembile.

Ukugcinwa komshini

- I-wire feeding mechanism. Kuhlanganisa nokuthi ibanga lokuphakela ngocingo lijwayelekile, noma ngabe ipayipi lokuphakela ngocingo lilimele, nokuthi ingabe kukhona i-alamu engavamile; Ukuthi ukugeleza kwegesi kujwayelekile; Ukuthi uhlelo lokuvikela ithoshi lokushisela lujwayelekile yini. (Akuvunyelwe ukuvala ithoshi yokushisela ngomsebenzi wokuvikela ukuphepha) ;Ukuthi uhlelo lokujikeleza kwamanzi lusebenza ngokujwayelekile yini;Hlola i-TCP (kunconywa ukuthi uhlanganise uhlelo lokuhlola futhi uluqalise ngemva kweshifu ngayinye)

2. Ukuhlolwa nokugcinwa kahle kwamasonto onke

1. Khuhla i-eksisi ngayinye yerobhothi; Hlola ukunemba kwe-TCP; Hlola izinga lamafutha asele. ;Hlola ukuthi ingabe indawo eyiziro ye-eksisi ngayinye yerobhothi inembile yini; Hlanza isihlungi ngemva kwethangi lamanzi lomshini wokushisela. Hlanza isihlungi endaweni efakwa umoya ecindezelwe; Hlanza ukungcola emlonyeni wethoshi lokushisela ukuze ugweme ukuvala ukujikeleza kwamanzi; Hlanza indlela yokuphakela ucingo, okuhlanganisa isondo lokuphakela ucingo, isondo lokucindezela izintambo kanye neshubhu lokuqondisa ucingo; Hlola ukuthi i-hose bundle kanye nepayipi lentambo yokuqondisa konakele noma kuphukile. (Kutuswa ukuthi ukhiphe yonke inqwaba yepayipi futhi uyihlanze ngomoya ocindezelwe);Hlola ukuthi uhlelo lokuvikela ukuphepha kwethoshi lokushisela luvamile yini nokuthi inkinobho yangaphandle yokumisa izimo eziphuthumayo ivamile yini.