Ezintathu ku-One Laser Welding Machine

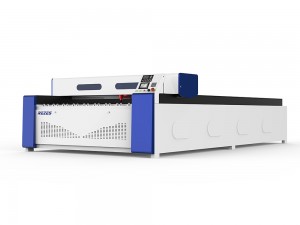

Isibonisi somkhiqizo

Ipharamitha yobuchwepheshe

| Isicelo | I-Laser Welding Cutting and Cleaning | Impahla Esebenzayo | Izinto zensimbi |

| I-Laser Source Brand | I-Raycus/MAX/BWT | CNC noma Cha | Yebo |

| Ububanzi be-Pulse | 50-30000Hz | I-Focal Spot Diameter | 50μm |

| Amandla Okukhiphayo | 1500W/2000W/3000W | Control Software | URuida/Qilin |

| Ubude be-Fiber | ≥10m | Ubude begagasi | 1080 ±3nm |

| Isitifiketi | CE, ISO9001 | Isistimu yokupholisa | Ukupholisa amanzi |

| Imodi yokusebenza | Okuqhubekayo | Isici | Ukunakekelwa okuphansi |

| Umbiko Wokuhlolwa Kwemishini | Kuhlinzekiwe | Ukuhlolwa kwevidiyo okuphumayo | Kuhlinzekiwe |

| Le yindawo ka Origin | I-Jinan, Isifunda saseShandong | Isikhathi sewaranti | 3 iminyaka |

Ividiyo Yomshini

Isici se-Three ku-One Laser Welding Machine

1. Ukuqina kwamandla aphezulu namandla aphezulu okushisela

I-laser beam energy density yomshini wokushisela we-fiber laser oqhubekayo uphakeme kakhulu, ongancibilikisa ngokushesha izinto zensimbi futhi wakhe i-weld eqinile. Amandla okushisela angalingana noma aphakeme nakakhulu kunalawo wento yomzali.

2. Ama-welds amahle, akukho ukucubungula okuthunyelwe okudingekayo

Ama-welds akhiqizwa nge-laser welding abushelelezi futhi afanayo, ngaphandle kokugaya okwengeziwe noma ukupholisha, okunciphisa kakhulu izindleko zokucubungula emva kokucubungula. Ifaneleka ngokukhethekile izimboni ezinezidingo eziphezulu zokubukeka kwe-welding, njengemikhiqizo yensimbi engagqwali, imboni yokuhlobisa insimbi, njll.

3. Isivinini se-welding esisheshayo kanye nokusebenza kahle kokukhiqiza okuthuthukisiwe

Uma kuqhathaniswa nezindlela zendabuko zokushisela (njenge-TIG/MIG welding), isivinini semishini yokushisela ye-fiber laser eqhubekayo inganyuswa izikhathi ezingu-2-10, ithuthukise kakhulu ukusebenza kahle kokukhiqiza, futhi ifanele izimo zokukhiqiza ngobuningi.

4. Indawo encane ethintekile ekushiseni kanye nokuguqulwa okuncane

Ngenxa yezici zokugxila ze-laser, okokufaka okushisa endaweni yokushisela kuncane, kunciphisa ukuwohloka kokushisa kwe-workpiece, efanelekile ikakhulukazi izingxenye zokunemba zokushisela, njengezingxenye ze-electronic, amadivaysi ezokwelapha, njll.

5. Ingakwazi ukushisela izinhlobonhlobo zezinto zensimbi, ezinohlu olubanzi lwezinhlelo zokusebenza

Isebenza kunsimbi engagqwali, i-carbon steel, i-aluminium alloy, ithusi, i-nickel alloy, i-titanium alloy nezinye izinsimbi nama-alloys azo, asetshenziswa kakhulu ekukhiqizeni izimoto, ukucubungula insimbi yeshidi, i-aerospace, izinto zikagesi, imishini yezokwelapha nezinye izimboni.

6. Izinga eliphakeme lokuzenzekelayo, lingahlanganiswa ne-robot welding

Umshini wokushisela we-fiber laser oqhubekayo ungahlanganiswa namarobhothi nezinhlelo ze-CNC ukuze kuzuzwe ukushiselwa okuzenzakalelayo, ukuthuthukisa izinga lokukhiqiza okuhlakaniphile, ukunciphisa ukungenelela okwenziwa ngesandla, nokuthuthukisa ukungaguquguquki kokukhiqiza nokuzinza.

7. Ukusebenza okulula kanye nezindleko eziphansi zokulondoloza

Izisetshenziswa zamukela i-interface yokuthinta yezimboni, imingcele eguquguqukayo, nokusebenza okulula; i-fiber laser inempilo ende (imvamisa ifinyelela emahoreni ayi-100,000) kanye nezindleko zokunakekela eziphansi, ezinciphisa kakhulu izindleko zokusebenzisa amabhizinisi.

8. Sekela izindlela eziphathwayo nezizenzekelayo

Ungakhetha inhloko ye-welding ephathwayo ukuze uzuze i-welding eguquguqukayo, efanelekile kuma-workpieces amakhulu noma angavamile; ingasetshenziswa futhi nebhentshi lomsebenzi elizenzakalelayo noma irobhothi ukuhlangabezana nezidingo zokukhiqiza umugqa wokuhlanganisa.

9. Imvelo futhi iphephile, ayikho i-welding slag, ayikho intuthu nothuli

Uma kuqhathaniswa nokushisela okujwayelekile, ukushisela nge-laser akukhiqizi intuthu eningi, izinhlansi, kanye ne-slag yokushisela, enobungani bemvelo futhi ephephile, futhi ehlangabezana nezindinganiso zesimanje zokukhiqiza eziluhlaza ezimbonini.

Amasampula Welding

Isevisi

1.Amasevisi enziwe ngokwezifiso:

Sihlinzeka ngemishini yokushisela i-fiber laser eyenziwe ngokwezifiso, eyenzelwe ngokwezifiso futhi yenziwe ngokwezidingo zamakhasimende. Noma ngabe okuqukethwe kokushisela, uhlobo lwempahla noma isivinini sokucubungula, singakulungisa futhi sikulungiselele ngokwezidingo eziqondile zekhasimende.

2.Ukubonisana ngaphambi kokuthengisa nokusekelwa kobuchwepheshe:

Sinethimba lonjiniyela abanolwazi abanganikeza amakhasimende izeluleko zokuthengisa zangaphambi kokuthengisa kanye nokwesekwa kobuchwepheshe. Kungakhathaliseki ukuthi ukukhethwa kwemishini, iseluleko sohlelo lokusebenza noma isiqondiso sobuchwepheshe, singanikeza usizo olusheshayo nolusebenzayo.

3.Impendulo esheshayo ngemva kokuthengisa

Nikeza usekelo lwezobuchwepheshe olusheshayo ngemva kokuthengisa ukuze uxazulule izinkinga ezihlukahlukene amakhasimende ahlangabezane nazo ngesikhathi sokusetshenziswa.

FAQ

Q: Yiziphi izinto ezingafakwa ezishiselwe ngomshini wokushisela we-laser?

A: Umshini wokushisela we-fiber laser oqhubekayo ulungele izinto ezihlukahlukene zensimbi, njengokuthi: insimbi engagqwali, i-carbon steel, i-aluminium alloy, ithusi, i-nickel alloy, i-titanium alloy, ishidi lama-galvanized, njll.

Ukuze uthole izinsimbi ezikhanyayo kakhulu (njengethusi, i-aluminium), kuyadingeka ukukhetha amandla e-laser afanelekile namapharamitha wokushisela ukuze uthole imiphumela emihle yokushisela.

Q: Iyini ubukhulu be-welding obukhulu be-laser welding?

A: Ubukhulu be-welding buncike emandleni we-laser.

Q: Ingabe i-laser welding idinga igesi yokuvikela?

A: Yebo, igesi yokuvikela (i-argon, i-nitrogen noma igesi exutshwe) ivamise ukudingeka, futhi imisebenzi yayo ihlanganisa:

- Vimbela i-oxidation ngesikhathi sokushisela futhi uthuthukise ikhwalithi yokushisela

- Yehlisa isizukulwane se-weld porosity futhi uthuthukise amandla okushisela

- Thuthukisa ukuqiniswa kwechibi elincibilikisiwe futhi wenze i-weld ishelele

Q: Uyini umehluko phakathi komshini wokushisela we-laser ophathwayo nomshini wokushisela we-laser othomathikhi?

A: Isandla: Ifanele ukusebenza okuguquguqukayo, ingashisela amajamo angajwayelekile kanye nezinto zokusebenza ezinkulu, ezifanele ukukhiqizwa kwenqwaba encane naphakathi.

I-Automation: Ifanele ukukhiqizwa okukhulu, okujwayelekile, ingahlanganisa izingalo zerobhothi nezindawo zokusebenza zokushisela ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza.

Q: Ingabe i-deformation izokwenzeka ngesikhathi sokushiswa kwe-laser?

A: Uma kuqhathaniswa nezindlela zendabuko zokushisela, i-laser welding inokufaka okuphansi kokushisa nendawo encane ethinteke ukushisa, futhi ngokuvamile ayikhiqizi ukuguquguquka okusobala. Okwezinto ezisetshenziswayo ezincanyana, amapharamitha angalungiswa ukuze kuncishiswe okokufaka okushisa futhi kuncishiswe nakakhulu ukuwohloka.

Q: Ingakanani impilo yesevisi yemishini?

IMP: Impilo yethiyori ye-fiber laser ingafinyelela "amahora angu-100,000", kodwa impilo yangempela incike endaweni yokusetshenziswa nokugcinwa. Ukugcina ukupholisa okuhle nokuhlanza njalo izingxenye ze-optical kungandisa impilo yemishini.

Q: Yiziphi izinkinga okufanele zinakwe lapho uthenga umshini wokushisela we-laser?

A: - Qinisekisa impahla yokushisela edingekayo nogqinsi, bese ukhetha amandla afanele

- Cabangela ukuthi i-automated welding iyadingeka yini ukuthuthukisa ukusebenza kahle kokukhiqiza

- Khetha umenzi onokwethenjelwa ukuze uqinisekise ikhwalithi yemishini kanye nesevisi yangemuva kokuthengisa

- Qonda ukuthi kuyadingeka yini ukupholisa okukhethekile noma izinhlelo zokuvikela