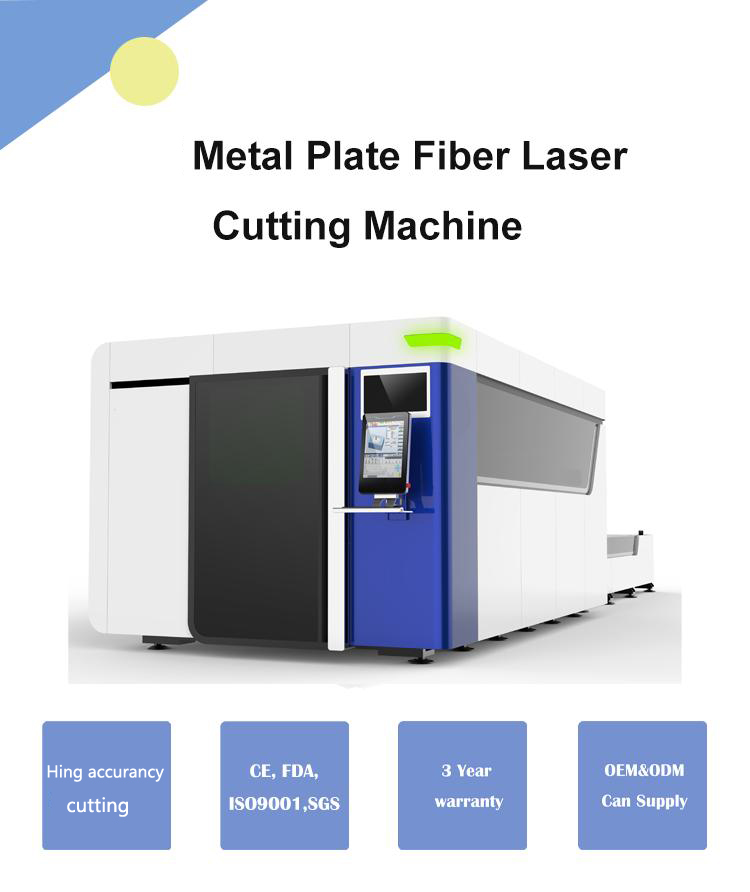

Umshini Wokusika Wekhava Yonke

Isibonisi somkhiqizo

Ipharamitha yobuchwepheshe

| Isicelo | I-Laser Cutting | Impahla Esebenzayo | Insimbi |

| Indawo Yokusika | 1500mm*3000mm | Uhlobo lweLaser | I-Fiber Laser |

| Control Software | I-Cypcut | I-Laser Head Brand | Ama-Raytools |

| I-Servo Motor Brand | Yaskawa motor | Umbiko Wokuhlolwa Kwemishini | Kuhlinzekiwe |

| Ifomethi Yomfanekiso Isekelwe | I-AI, PLT, DXF, BMP, Dst, Dwg, DXP | CNC noma Cha | Yebo |

| Amaphuzu Okuthengisa Abalulekile | Ukunemba okuphezulu | Isisindo | 4500kg |

| Imodi yokusebenza | okuzenzakalelayo | Ukunemba Kokumisa | ±0.05mm |

| ukunemba kokubeka kabusha | ±0.03mm | Ukusheshisa Okuphakeme | 1.8G |

| Izimboni Ezisebenzayo | Amahhotela, Izitolo Zezinto Zokwakha, Imboni Yokukhiqiza | Izingxenye zomoya | I-SMC |

| Imodi yokusebenza | igagasi eliqhubekayo | Isici | Ikhava egcwele |

| Isivinini sokusika | kuye ngamandla nokuqina | Control Software | I-Tubepro |

| Ukusika Ukujiya | 0-50 mm | I-Guiderail Brand | HIWIN |

| Izingxenye zikagesi | schneider | Isikhathi sewaranti | 3 iminyaka |

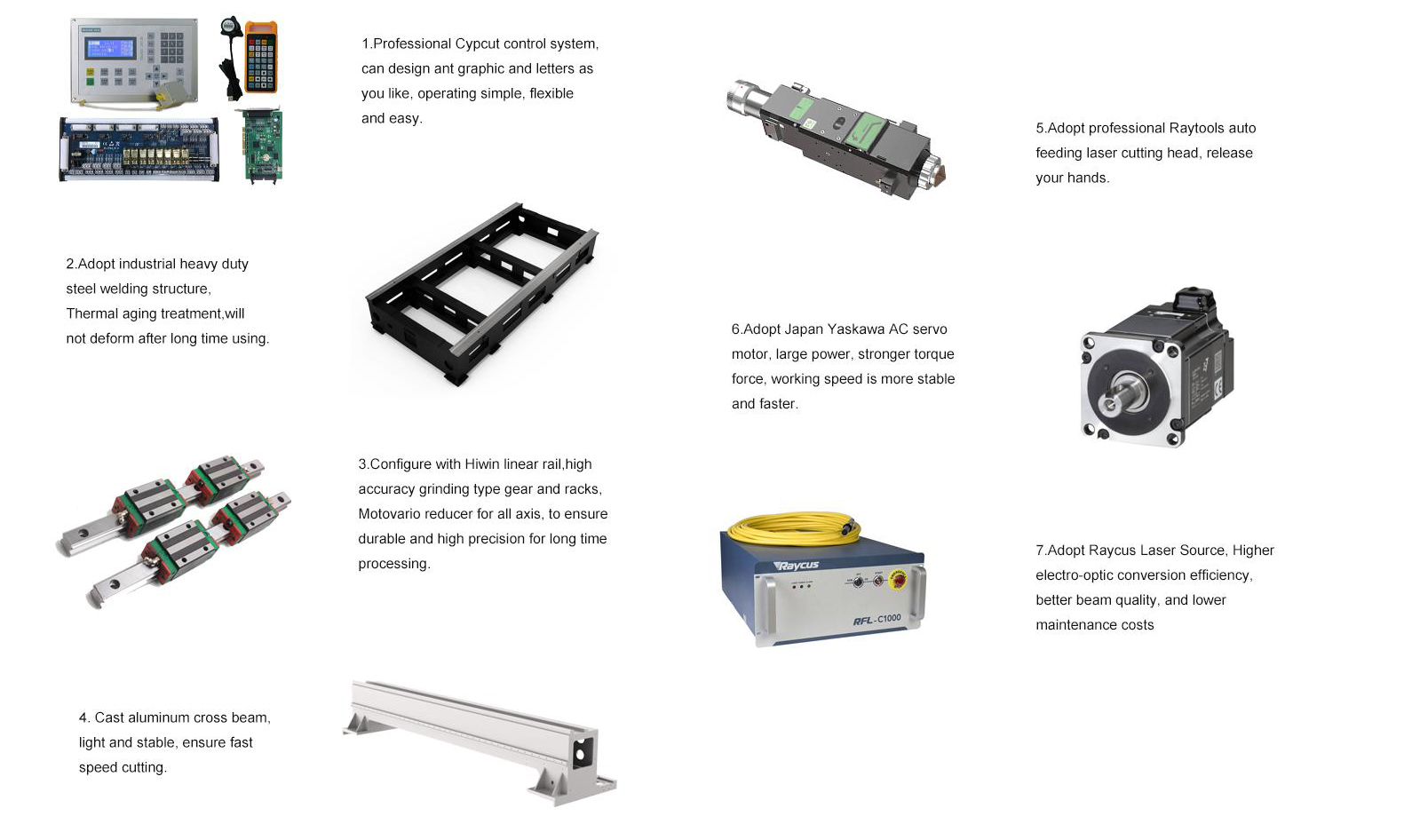

Izingxenye zomshini

Ividiyo Yomshini

Umshini Wokusika Wekhava Yonke

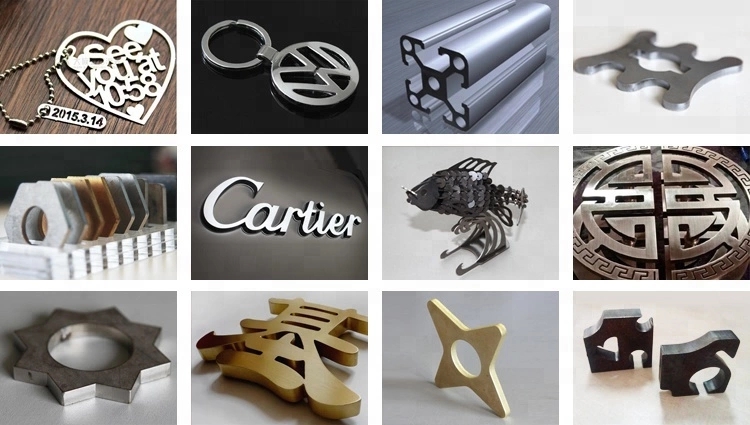

Ukusika amasampula

Isicelo

1. Imboni yezimoto

Imishini yokusika i-laser isetshenziswa kumakhava angaphambili emoto, insimbi yeshidi lemoto, amapayipi okukhipha umoya wemoto, njll., futhi idinga ukucutshungulwa ngemuva kokwenza amanye amakhona noma ama-burrs. Uma kusetshenziswa ukusebenza okwenziwa ngesandla, kunzima ukufeza izinga elifiswayo lokusebenza kahle nokunemba.

2. Imboni yokuhlobisa

Imboni yokuhlobisa idinga ukusebenzisa ihluzo eziningi eziyinkimbinkimbi, futhi umshini wokusika we-laser ungahlangabezana nokusetshenziswa kwalo mkhakha ngesivinini sokusika nokusika okuguquguqukayo, futhi uthandwa kakhulu phakathi kwezinkampani zokuhlobisa. Ngemva kokuklama imidwebo efanele, ukungenisa ngokuchofoza okukodwa kunganqanyulwa.

3.Imboni yokukhangisa

Imishini Yokusika I-Fiber Laser isetshenziswa kabanzi ekukhiqizeni i-Billboard, Ukukhangisa, Izimpawu, Izimpawu, Izinhlamvu Zensimbi, Izinhlamvu ze-LED.

4.Imishini yasendlini kanye nemboni yezimpahla zasekhishini

Imishini yasendlini kanye nezitsha zasekhishini ngokuyisisekelo zenziwe ngamapuleti amancane. Ngaphambi kwenqubo yokugxiviza nokudweba, umshini wokusika i-fiber laser usetshenziselwa ukucubungula amasampula ukuthuthukisa ngokushesha imikhiqizo emisha. Ijubane lokusika lemishini yokucubungula i-laser liyashesha, okuthuthukisa kakhulu ukusebenza kahle kokucubungula. Ngesikhathi esifanayo, imishini yokucubungula i-laser inokunemba okuphezulu kokusika, okuthuthukisa isivuno sama-hood ahlukahlukene kanye nemishini evuthayo. Kweminye imikhiqizo emise okukhethekile, imishini yokusika i-fiber laser inezinzuzo eziyingqayizivele, kufaka phakathi amakhabethe okusabalalisa amandla, amakhabethe okugcwalisa, njll., konke okuwukukhiqizwa okujwayelekile kwamapuleti amancane futhi kudinga ukusebenza kahle. Ukusetshenziswa kwemishini yokusika i-laser kungathuthukisa kakhulu ukusebenza kahle.

5.Imboni yemishini yezolimo

Kunezinhlobo eziningi zezingxenye zokucubungula zensimbi zeshidi zemikhiqizo yemishini yezolimo, futhi zibuyekezwa ngokushesha. Izingxenye zokucubungula zensimbi zeshidi zemikhiqizo yemishini yezolimo ngokuvamile zisebenzisa indlela yokubhoboza, edla isikhunta esiningi. Uma ukucutshungulwa kwezingxenye kusahlala ngendlela evamile, kuzokhawulela kakhulu ukushintshwa kwemikhiqizo. Izici zokucubungula eziguquguqukayo ze-laser ziyabonakala. Ukucutshungulwa kwe-Laser kungabona ukusikwa kwezinhlobo ezahlukahlukene zamapuleti ngosizo lwesoftware yokuhlela. Ukusebenzisa ukucubungula kwe-laser akugcini nje ngokusheshisa ukucutshungulwa kwejubane, ukusebenza kahle okuphezulu, kanye nezindleko eziphansi, kodwa futhi akudingi ukubuyisela isikhunta noma amathuluzi, kufinyeze isikhathi sokulungiselela ukukhiqiza. Ingakwazi futhi ukuhambisana nesivinini lapho umkhiqizo uvuselelwa, futhi isitayela esisha singasikwa ngokudwetshwa kabusha nokuhlela. Kulula ukubona ukucubungula okuqhubekayo, isikhathi sokuguqulwa kwe-laser sifushane, futhi ukusebenza kahle kokukhiqiza kuphezulu. Ama-workpiece ahlukahlukene angafakwa ngokushintshana. Lapho i-workpiece icutshungulwa, izingxenye eziqediwe zingasuswa futhi i-workpiece ezocutshungulwa ingafakwa ukuze kusebenze ukucutshungulwa okufanayo.

6.Imboni yemishini yokwakha

Embonini yemishini yokwakha, izimbobo eziyisiyingi zokusika i-fiber laser zingasetshenziswa inqobo nje uma ububanzi bomgodi oyindilinga wokusebenza bukhulu noma bulingana nobukhulu bepuleti, futhi izidingo zokuqina nobubanzi zingaphakathi komthamo oqinisekisiwe womshini wokusika lapho ubhekene nogqinsi oluthile lwepuleti. I-laser isika ngokuqondile impahla, isuse inqubo yokumba futhi ithuthukise ukusebenza kahle kokukhiqizwa kwabasebenzi. Kwezinye izinto zokusebenza ezinezimbobo eziningi, umsebenzi wokubona umshini wokusika i-fiber laser usetshenziselwa ukunquma indawo yomgodi, okusindisa isikhathi sokubeka imbobo yenqubo yokumba imbobo elandelayo, futhi konga izindleko zokukhiqiza zesifanekiso sokumba, esingagcini nje ngokuthuthukisa ukusebenza kahle kokukhiqiza, kodwa futhi sithuthukise ukunemba komkhiqizo.