Amasu okusika endabuko ahlanganisa ukusika ilangabi, ukusika i-plasma, ukusika i-waterjet, ukusika izintambo nokubhoboza, njll. Umshini wokusika i-Fiber laser, njengendlela esafufusa eminyakeni yamuva nje, uwukukhanyisela isigxobo se-laser esinamandla aphezulu ku-workpiece ezocutshungulwa., ukuncibilikisa ingxenye ngokufudumeza, bese usebenzisa igesi yokucindezela okuphezulu ukuze uqhume i-slag ukuze wenze ukuqhekeka.Umshini wokusika we-laser unezinzuzo ezilandelayo.

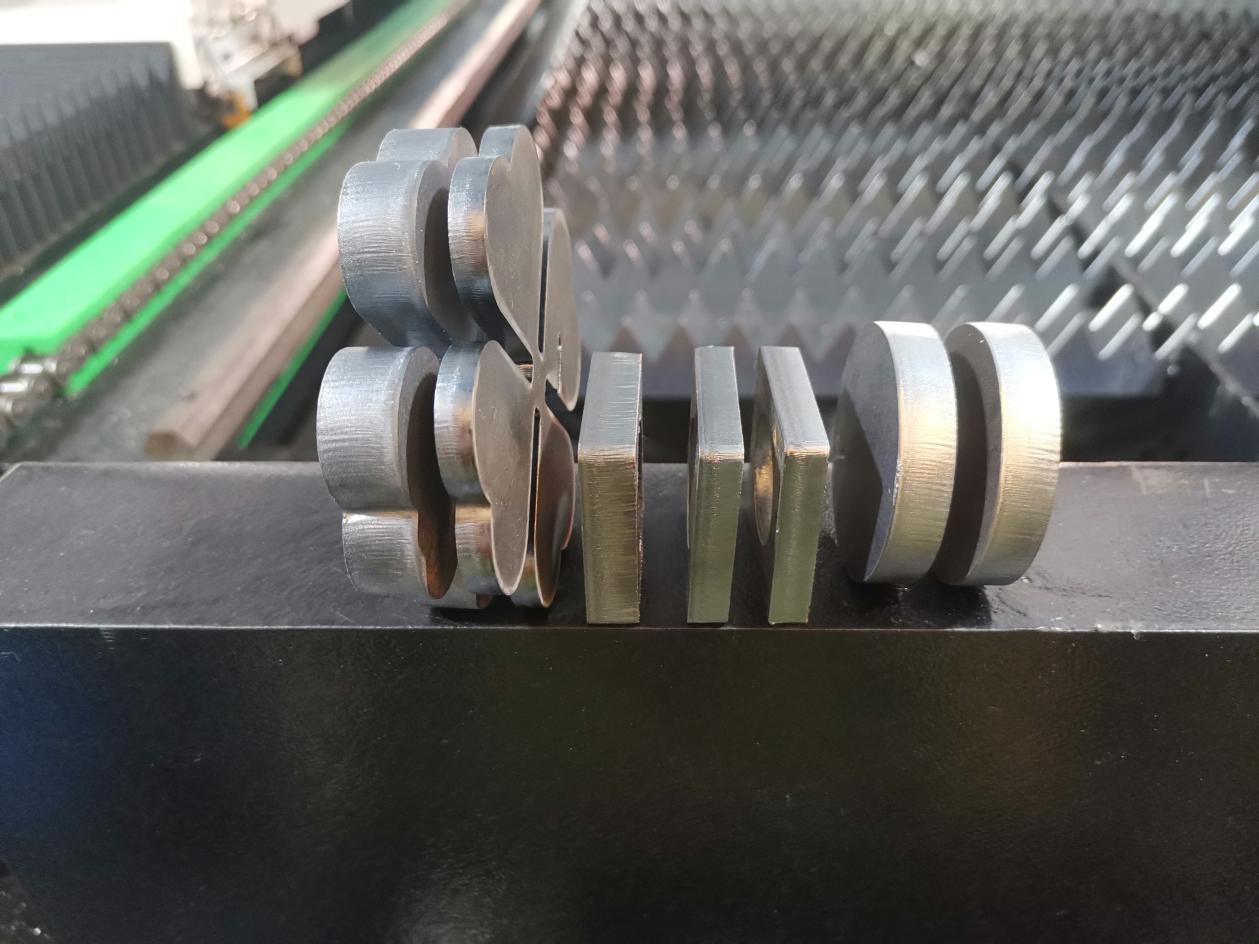

1. I-kerf incane, ukunemba kuphezulu, ukugoqa kwe-kerf kuhle, futhi asikho isidingo sokucutshungulwa kabusha enqubweni elandelayo ngemva kokusika.

2. Uhlelo lokucubungula nge-laser ngokwalo luwuhlelo lwekhompiyutha, olungahlelwa kalula futhi lulungiswe, futhi lufanele ukucutshungulwa komuntu siqu, ikakhulukazi izingxenye ezithile zeshidi lensimbi elinemikhonto eyinkimbinkimbi kanye nokuma.Amaqoqo makhulu futhi umjikelezo wempilo yomkhiqizo awumude.Ngokombono wezobuchwepheshe, izindleko zezomnotho kanye nesikhathi, akubizi kakhulu ukwenza isikhunta, futhi ukusika i-laser kunenzuzo ikakhulukazi.

I-3.Ukucutshungulwa kwe-Laser kunomthamo omkhulu wamandla, isikhathi esincane sesenzo, indawo encane ethinteke ukushisa, ukuguqulwa okuncane kokushisa, nokucindezeleka okuncane kokushisa.Ngaphezu kwalokho, i-laser iyi-non-mechanical contact processing, engenakho ukucindezeleka komshini ku-workpiece, futhi ifanele ukucubungula ngokunemba.

4. Umthamo omkhulu wamandla we-laser wanele ukuncibilikisa noma iyiphi insimbi, ikakhulukazi efanelekile ukucubungula ezinye izinto ezinobunzima obuphezulu, ukuqina okuphezulu kanye nephuzu elincibilikayo eliphakeme okunzima ukulicubungula ngamanye amasu.

5. Izindleko eziphansi zokucubungula.Ukutshalwa kwezimali kwesikhathi esisodwa kwezinto zokusebenza kubiza kakhulu, kodwa ukucubungula okuqhubekayo nokukhulu ekugcineni kunciphisa izindleko zokucubungula zengxenye ngayinye.

6. I-laser iyi-non-contact processing, ene-inertia ephansi kanye nesivinini sokucubungula okusheshayo.Ukusebenzisana nohlelo lwesoftware ye-CAD/CAM yohlelo lokulawula izinombolo, konga isikhathi futhi kulula, futhi ukusebenza kahle kukonke kuphezulu.

7. I-laser inezinga eliphezulu lokuzenzekelayo, lingavalwa ngokugcwele ukuze licutshungulwe, alinakho ukungcola, futhi linomsindo ophansi, okuthuthukisa kakhulu indawo yokusebenza yabaqhubi.

Isikhathi sokuthumela: Apr-23-2023